Overview

The Felco Bedding Conveyor System was developed by John Felton, the founder of Felco. He was a sewer / water contractor in the Seattle and Portland area, and developed the attachment as a way to get bedding material into the trench on tight jobs. It is still a mainstay on large pipe jobs nationwide.

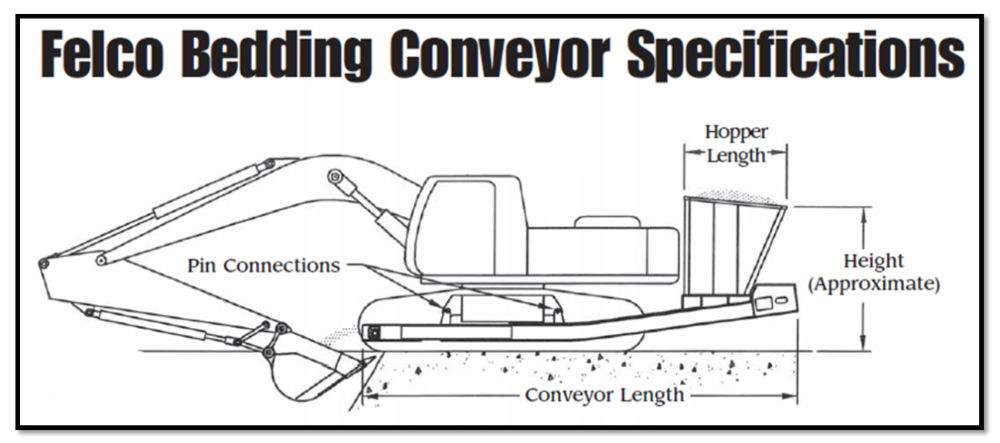

The Bedding Conveyor allows pipe bedding material to be delivered and placed with the lead excavator. A hopper behind the excavator is filled with bedding material, then a hydraulic motor runs the conveyor belt which transfers the material that comes out the bottom of the hopper between the excavator tracks to the front of the excavator. Typically operators shoot the amount of material they need into their digging bucket to then place on the pipe in the trench.

The entire system is operated from the cab. The Felco Bedding Conveyor replaces cumbersome bedding boxes, reduces the time it takes to bed a piece of pipe, minimizes waste of material and keeps the excavator operator’s attention on the trench.

The Felco Bedding Conveyor can deliver one cubic yard of bedding material from the hopper to the front of the excavator every 7 – 10 seconds. With five different models to accommodate 100 class excavators and up, the bedding conveyors can accommodate a wide range of machines. Additionally, with bolt-in Conveyor Extensions, Felco Bedding Conveyors can be moved to other excavators and mounted with the purchase of an additional installation kit.

Once mounted, the Bedding Conveyor can be removed or reattached within 10 minutes.

How do Felco Bedding Conveyors help you put more sewer and water pipe in the ground than any other method? With the Bedding Conveyor, you control when, where and how much bedding material is placed in the trench while bedding pipe.

- Use only the amount of bedding material you need. The hopper contains your bedding material, which means no material is wasted on the ground. A job site loader is the best method of charging the hopper with material.

- Reduce machine swing cycle time by almost 75%. Material is held in the hopper and transferred via conveyor belt under the car body to your waiting bucket, to be placed and used as needed when the pipe crew is ready.

- Eliminate the need for flaggers and road closures. Only a single lane is necessary because material is loaded into the hopper located directly behind the excavator.

- SAFETY – the excavator operator controls the conveyor from the cab, maintaining a direct line of site into the trench and on either side. Additionally, filling the hopper with material and using the conveyor, rather than dumping from the side of the trench, keeps a loader away from the trench edge. That means less opportunity for accidents.

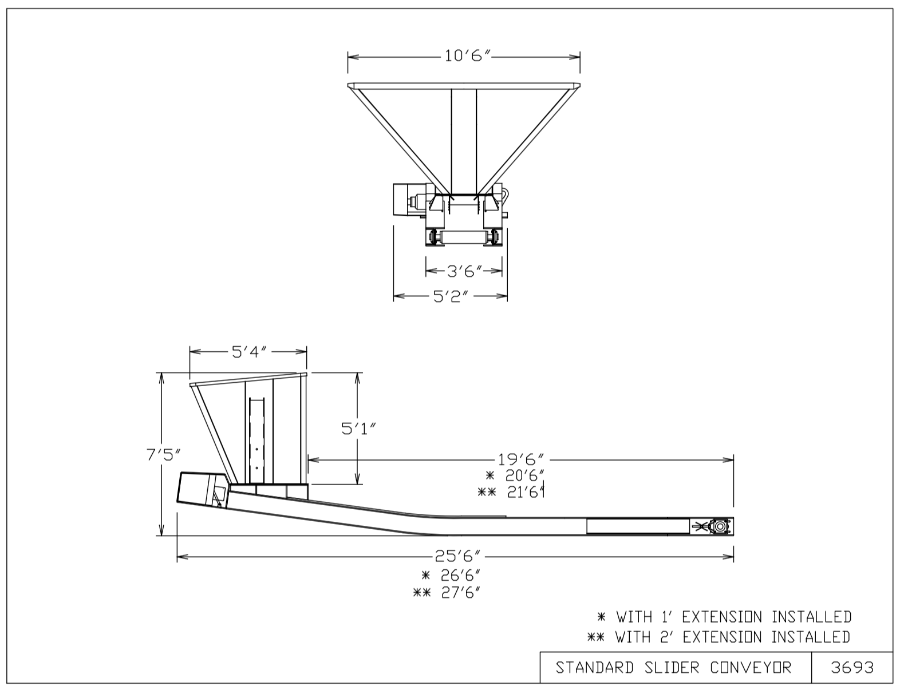

| Machine Weight (LBS) | Model | Length | Height | Width | Hopper Capacity | Belt Width | Est. Weight (LBS) |

| 20,000 – 40,000 | EX | CUSTOM | 6’6″ | 9’6″ | 2CY | 18″ | 6,000 |

| 20,000 – 70,000 | CD | 12’6″ – 28’6″ | 6’6″ | 10′ | 3CY | 24″ | 7,200 |

| 70,000 – 120,000 | STD | 25’6″ – 27’6″ | 7’6″ | 10’6″ | 4CY | 24″ | 7,500 |

| 80,000 – 150,000 | RLR | 25’6″ – 31’6″ | 7’6″ | 10’6″ | 4CY | 24″ | 8,000 |

| 150,000 – 250,000 | Model 60 | 31′ | 9’6″ | 12′ | 8CY | 30″ | 10,200 |

Bedding Conveyor Hopper Vibratory Kits mount on the hopper. When the conveyor’s hydraulic motor is activated to move the belt, the hopper vibrator also shakes the hopper. Best used if bedding material is prone to bridging.

Hopper Grates are available to screen out bedding material that contains occasional larger rocks or material which might restrict material movement in the bottom of the hopper. 2CY, 3CY, 4CY, and 8CY hopper sizes available.

Typically Bedding Conveyor installation is performed by the excavator dealership or by the contractor. Felco can provide assistance remotely or on site, but a competent welder equipped with a welding machine and acetylene torch and supplies, as well as a mechanic equipped to work on hydraulics, electrical, and mechanical systems, are key.

Prior to receiving the Bedding Conveyor, we suggest a conference call with our installation specialists regarding the installation requirements. This will save time and effort on the installation process.

An excavator-specific installation kit is included with each Bedding Conveyor, which includes mounting hardware, major electrical and hydraulic components, and valves and hoses specific to the excavator.