Overview

Felco Tamping Pad Wheel Compactors work particularly well in cohesive soils by focusing compaction down and out through the staggered tamping pad bumps. Within the rigid exterior frame, Felco uses our proven Sealed Journal Bearing System so the strength of the axle assembly, combined with its maintenance-free design (no greasing) provides superior performance and less downtime due to its ability to withstand heavy use.

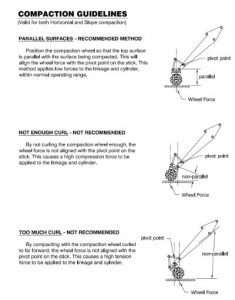

Excavator operators use Felco Wheel Compactors typically when the extra extension range of the wheel is preferable, and contractors consistently report achieving 90% + compaction in most soil types throughout the U.S. and Canada.

Bi-directional scraper teeth assemblies come in two options – Standard & Aggressive – which remove excess material between the rows of bumps. The replaceable X156 dirt teeth are a standard size and available from most dealers.

Felco’s Sealed Journal Bearing System requires NO DAILY MAINTENANCE and is supported by an industry best FIVE-YEAR LIMITED WARRANTY.

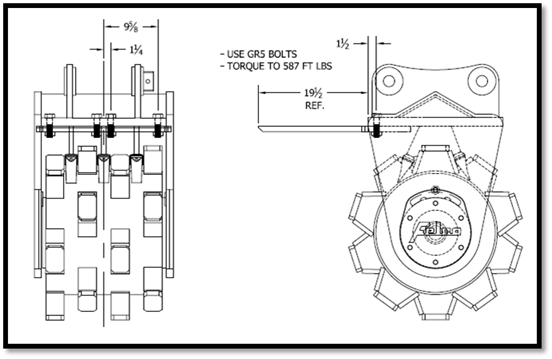

Bolt-On Ear Assemblies are standard with each wheel compactor – which allows use on other similar class excavators with different ear dimensions by purchasing an additional bolt-on ear assembly from Felco.

Machine Weight

(lbs.) | Standard Size

(Width” x Diam.”) | Est. Weight (lbs.) | Sealed Journal Bearing |

| 17,000 – 32,000 | |||

| 18 x 27 | 750 | SJB – I | |

| 24 x 27 | 825 | SJB – I | |

| 30 x 27 | 1,000 | SJB – F | |

| 32,000 – 60,000 | |||

| 18 x 31 | 1,100 | SJB – E | |

| 24 x 31 | 1,400 | SJB – E | |

| 30 x 31 | 1,800 | SJB – E | |

| 36 x 31 | 2,200 | SJB – H | |

| 60,000 – Up | |||

| 18 x 41 | 1,750 | SJB – E | |

| 24 x 41 | 1,950 | SJB – E | |

| 30 x 41 | 2,200 | SJB – E | |

| 36 x 41 | 2,575 | SJB – H | |

| 42 x 41 | 3,000 | SJB – H | |

| 48 x 41 | 3,500 | SJB – H | |

| 60 x 41 | 4,626 | SJB – H |

– BOLT ON EAR ASSEMBLY to match OEM specs for excavator is standard feature.

– SJB – Felco Sealed Journal Bearing System (No Maintenance Required)

– Replaceable Scraper Teeth

– FIVE YEAR LIMITED WARRANTY

Linkage Pins

Available from 40mm to 130mm diameters

Bolt-On Leveling Blades

Felco Bolt-On Leveling blades can be mount on either side of the ear assembly, depending on how an operator prefers to push/pull material into the trench.

Replaceable Scraper Teeth / Adapters

Worn scraper teeth are easy to remove and replace. Scraper teeth keep the wheel clean and will improve the performance of your compaction attachment.

Bolt-On Ear Assemblies

Bolt-On Ear Assemblies are standard with each full size wheel compactor – which allows use on other similar class excavators with different ear dimensions by purchasing an additional bolt-on ear assembly from Felco.

Please provide the serial # on the Wheel Compactor which is located between the current set of ears, and the Make / Model of the excavator that you want the new ears to mount on.

To confirm ear dimensions, please click on this Ear Dimensions Confirmation Sheet.

For sizing and pricing questions, please call our Parts Department at 800-221-5427, then press 1.