Overview

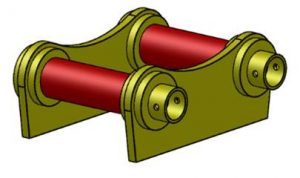

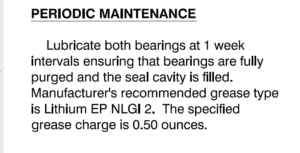

Felco Mini Ex Wheel Compactors have a specially designed wheel assembly to ensure optimal compaction, while featuring greaseable flange bearings instead of our sealed journal bearing to reduce weight for use with mini excavators.

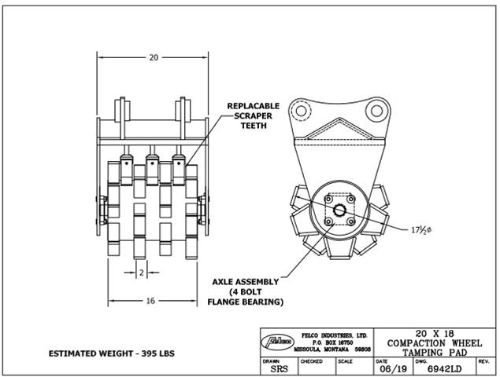

TAMPING PAD STYLE WHEEL COMPACTOR

SEGMENTED STYLE WHEEL COMPACTOR

Tamping Pad | 12 x 18 | 325 | FLG | $4,593 |

Tamping Pad | 16 x 18 | 375 | FLG | $4,726 |

Tamping Pad | 18 x 18 | 425 | FLG | $4,940 |

Tamping Pad | 20 x 18 | 475 | FLG | $5,121 |

Tamping Pad | 24 x 18 | 575 | FLG | $5,511 |

|

|

|

|

|

Segmented | 12 x 18 | 237 | FLG | $4,593 |

Segmented | 16 x 18 | 245 | FLG | $4,726 |

Segmented | 18 x 18 | 310 | FLG | $4,940 |

Segmented | 20 x 18 | 375 | FLG | $5,121 |

Segmented | 24 x 18 | 498 | FLG | $5,511 |

Standard Features:

Fixed Ear Assembly to match OEM specs for backhoe or excavator

FLG – Greaseable Flange Bearings

Options Include:

Linkage Pins

Dedicated Leveling Blades

NOTE:

We currently have a steel surcharge in effect. We are assessing $0.40 / lb. based on the estimated attachment weight.

Felco recommends quoting our products through your preferred excavator dealership. Typically dealers can offer pricing incentives on our products. Please have your sales rep contact us for a dealer quote.

Linkage Pins

Replaceable Scraper Teeth / Adapters for Tamping Pad Wheel

Worn scraper teeth are easy to remove and replace. Scraper teeth keep the wheel clean and will improve the performance of your compaction attachment.

Replacement Ears

Felco can send a set of replacement pin-on ears for your current Felco Mini EX Wheel Compactor, to use your attachment on a different, similar class excavator.

Please provide the serial # on the Wheel Compactor which is located between the current set of ears, and the Make / Model of the excavator that you want the new ears to mount on.

To confirm ear dimensions, please click on this Ear Dimensions Confirmation Sheet.