Overview

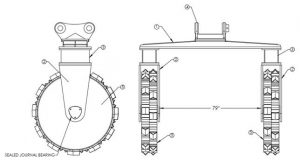

Felco Straddle Wheel Compactors are designed to efficiently and uniformly backfill large diameter pipe. Within the rigid exterior frames, Felco uses our proven Sealed Journal Bearing System so the strength of the axle assemblies, combined with their maintenance-free design (no greasing) provides superior performance and less downtime due to its ability to withstand heavy use and is supported by our industry best 5-YEAR LIMITED WARRANTY.

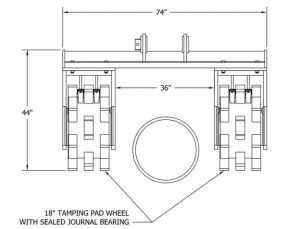

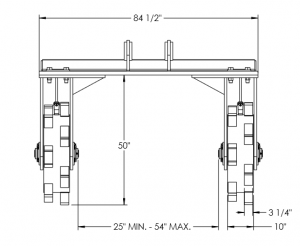

Straddle Wheel Compactors are “semi-custom” for your specific needs to match up with pipe diameter and project requirements. Distance between the wheels can be manual adjusted, and we also can offer hydraulic width-adjusting systems.

Features include:

- Internal width between the wheels can be specified to your needs. We typically build them with some adjustability. Loosen 4 bolts per wheel, slide the leg assembly to the desired position, and re-tighten.

- Wheel diameter can be modified to most anything you want. We typically try to keep it below trucking width limits so we don’t run into additional shipping costs, but past that, it can be whatever you want.

- We recommend a 12” compactor wheel width because we can utilize our sealed journal bearing axles. This gets you no daily maintenance and a 5-YEAR LIMITED WARRANTY on the axle. Narrower wheel width is possible, but we must drop to a flange bearing. This requires daily greasing and usually only a 90 warranty from the manufacturer.

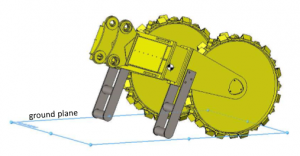

- We have optional, removable spacer blocks to get the wheels deeper into the trench from the beam. We also offer optional, removable “kick stands” that keep the ear assembly up off the ground if you are utilizing a quick coupler.

- Lastly, all our designs have a bolt-on ear assembly so the attachment can be swapped between machines without too much difficulty. You only need a second ear plate.

Please call Felco Industries to discuss sizing options for the Felco Straddle Wheels – we build these custom to match up with the project and the excavator.

Linkage Pins

Available from 40mm to 130mm diameters

Slotted Top Plate for Width Adjustment

Bolt-On Ear Assemblies

Bolt-On Ear Assemblies are available on the Straddle Wheel Compactor – which allows use on other similar class excavators with different ear dimensions by purchasing an additional bolt-on ear assembly from Felco.

Please provide the serial # on the Straddle Wheel Compactor which is located between the current set of ears, and the Make / Model of the excavator that you want the new ears to mount on.

To confirm ear dimensions, please click on this Ear Dimensions Confirmation Sheet.

Bolt-On Wheel / Frame Assemblies

Bolt-On Ear Wheel / Frame Assemblies are available on the Straddle Wheel Compactor – which allows use of different wheels and/or frame lengths for different diameter pipe.

Straddle Wheel “kickstands” for easier mounting / dismounting with the excavator.

Removable Spacer Blocks

Removable spacer blocks to get the wheels deeper into the trench from the beam.