Built extra stout to punch through and rip up frost and rock.

Overview

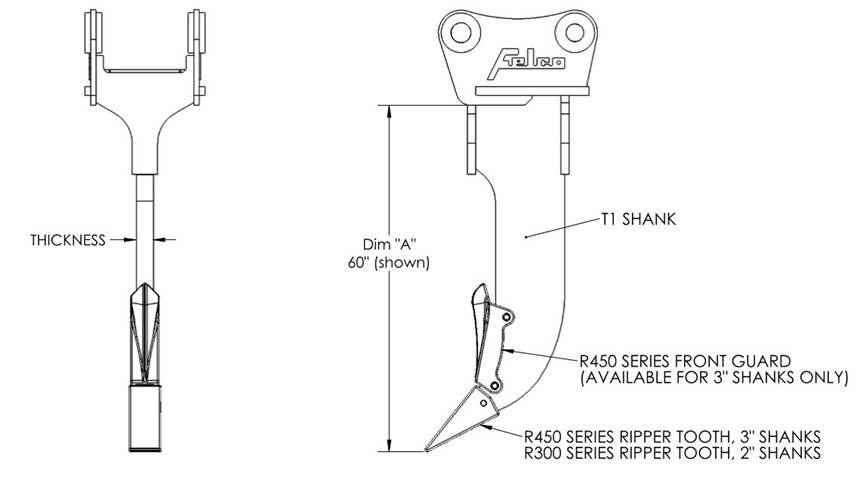

Felco Excavator Ripper Shanks are built extra stout to deal with the difficulties of soils compacted by deep frost and designed to punch through and rip up the frost layer. By attaching the shank to the ear assembly via heavy cross members, this greatly reduces stress concentrations in the welds and distributes load more evenly from the shank to the ears. Additionally this design increases the strength factor of these rippers considerably.

Standard lengths from 26” to 60” are available, and custom requests are welcomed.

Machine Operating Weight (LBS) | Ripper Shank Length (in.) | T-1 Shank Width (in.) | Est. Weight (LBS) |

| 16,000 – 25,000 | |||

| 26” | 2” | 390 | |

| 30” | 2” | 415 | |

| 25,000 – 45,000 | |||

| 26” | 2” | 570 | |

| 30” | 2” | 595 | |

| 36” | 3” | 745 | |

| 45,000 –65,000 | |||

| 36” | 3” | 940 | |

| 42” | 3” | 1,000 | |

| 48” | 3” | 1,110 | |

| 65,000 – 100,000 | |||

| 36” | 3” | 1,090 | |

| 42” | 3” | 1,155 | |

| 48” | 3” | 1,230 | |

| 60” | 3” | 1,360 | |

| 100,000 – 150,000 | |||

| 36” | 3” | 1,510 | |

| 42” | 3” | 1,570 | |

| 48” | 3” | 1,700 | |

| 60” | 3” | 1,820 | |

| 150,000 – 200,000 | |||

| 36” | 4” | 1,740 | |

| 42” | 4” | 1,800 | |

| 48” | 4” | 1,930 | |

| 60” | 4” | 2,050 |

Each Ripper includes:

o ROMAC Replaceable Wear Tooth

o Dedicated Ear Assembly to match OEM specs for excavator

ROMAC Front Ripper Rock Guards are optional on 3” & 4” wide rippers

Linkage Pins

Available from 40mm to 130 mm diameters

ROMAC Replaceable Wear Tooth

ROMAC Front Ripper Guard – w/ pins & retainers (Optional on 3″ width shanks)

Coming Soon!